Tube Laser Cutting Systems 130 Watt

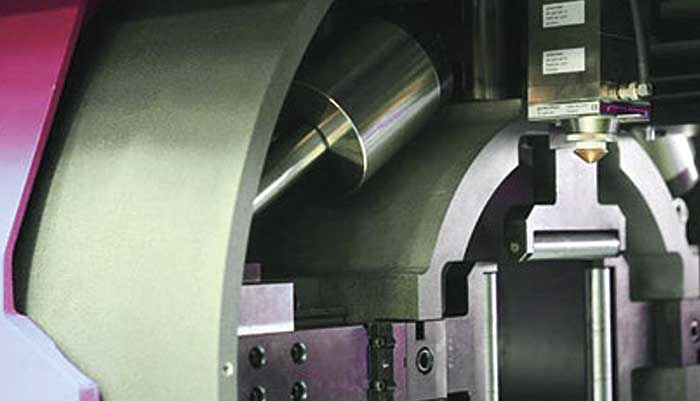

Some things are difficult to see until you have a closer look at the fiber laser operating. Fiber lasers have a larger power density than CO2 laser beams because their beam diameter is typically one-third that of CO2 beams. This allows fiber to cut more quickly and also allows it pierce better. This allows the fiber to cut intricate shapes with sharp edges and leaves a smaller beam size. Imagine that a fiber can cut the company logo from a tube with spacing of 0.035 in between its letters; a CO2 laser is incapable of doing this.

PowerLine C are CO2 laser-based systems for precision drilling, cutting, scribing, marking, and engraving of many non-metals, including glass, organic materials.